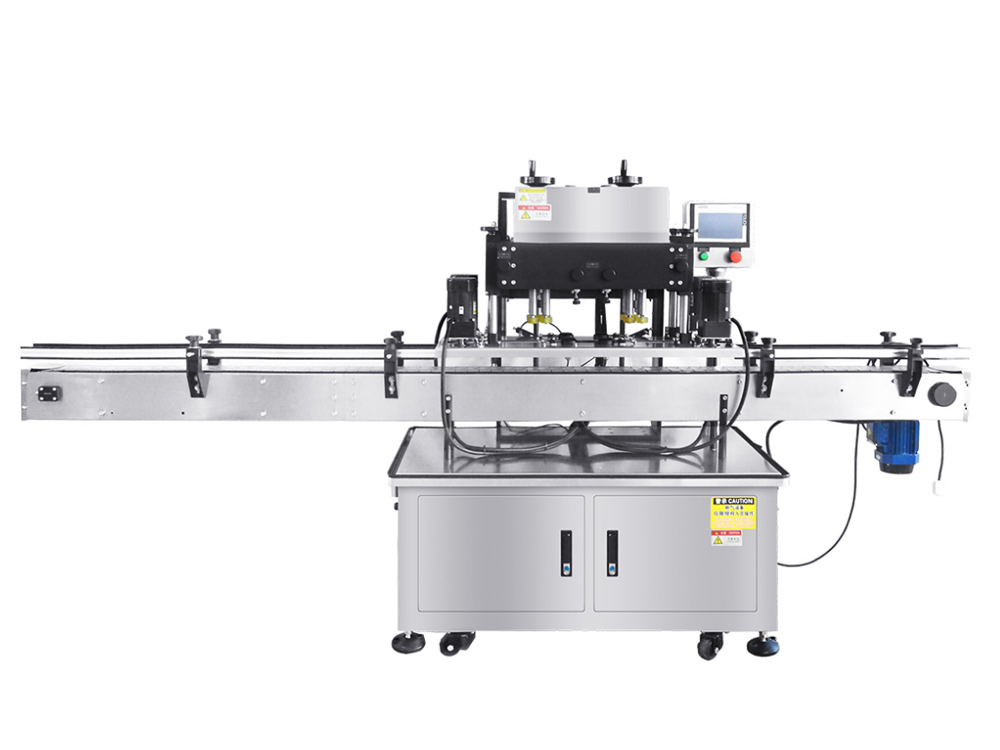

Product Description

The fully automatic capping machine is an improved design based on international advanced models, with fast capping speed, high qualification rate, and easy operation. Can be used for different bottle shapes of screw caps in industries such as food, pharmaceuticals, daily chemicals, pesticides, cosmetics, etc. Four speed regulating motors are used for capping, bottle clamping, conveying, and capping. The machine has a high degree of automation, good stability, and easy adjustment. When replacing bottle shapes or caps, no spare parts are needed, only adjustments are needed (if equipped with a capping machine, automatic capping can be performed, and corresponding lifting and capping machines or vibrating disc capping machines can be matched according to the shape of the bottle cap). It can be selected according to actual needs.

Principle of automatic capping machine: electrically controlled movement, strong stability; Equipped with positioning device, standard screw cap, easy to operate; Wide locking range, capable of locking bottle caps of different shapes and specifications; It solves the problem that it is difficult to screw the cover of nozzles, pump heads, spray pumps and hand button nozzles; The locking speed can be adjusted, and the tightness can be adjusted according to different bottle caps.

Features of automatic capping machine:

1. Stainless steel material+lightweight aluminum profile production

2. This machine has good compatibility and can be used with various common bottle caps. And the operation is simple.

3. Excellent flexibility, adjustable according to bottle height and cap size, and adjustable according to customer requirements for tightness.

4. The capping wheel is made of wear-resistant silicone, which does not damage the bottle cap.

5. Can be used on filling production lines.

Technical Parameter

Model | TF-XGJ |

Power supply voltage (V/Hz) | AC 220/50 |

Power (W) | 1500 |

Sealing height (mm) | 38-300 |

Suitable cover diameter (mm) | 22-85 |

Suitable bottle diameter (mm) | 35-130 |

Working pressure (MPa) | 0.3-0.5 |

Production capacity (bottles/minute) | 2000-3500/hour |

Dimensions (L × W × H) (mm) | 2000X800X1600 |

Net weight (kg) | 200 |