TFTC-RD-10 ten head peristaltic pump …

SKY SAIL

Contact person:Mr. Han

Mobile phone:18939701369

Email:517596347@qq.com

Address:No. 7238, Daye Highway, Fengxian District, Shanghai

TFTC-RD-10 ten head peristaltic pump …

TFTC-CL-2 Double ended Gear Pump Fill…

TFTC-CZ-6 Head Weighing Filling Machi…

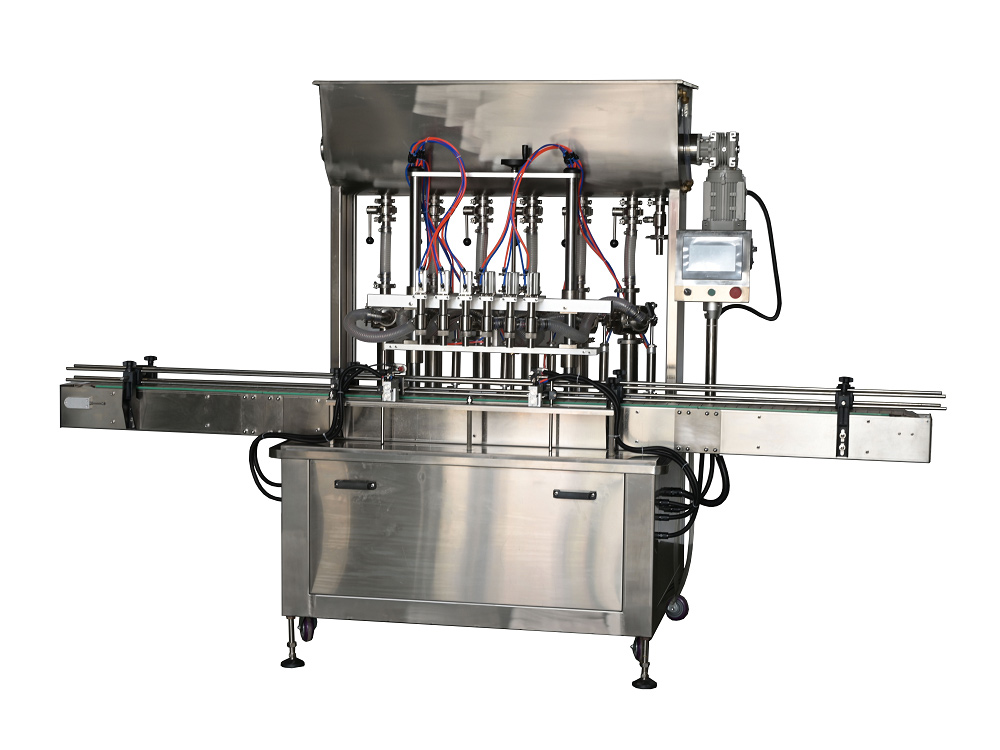

TFTC-HS-12 Head Fully Private Server …

TF-KGF-40 Star Plate oral Liquid…

TF-GZJ-YT600 fully automatic linear 6…