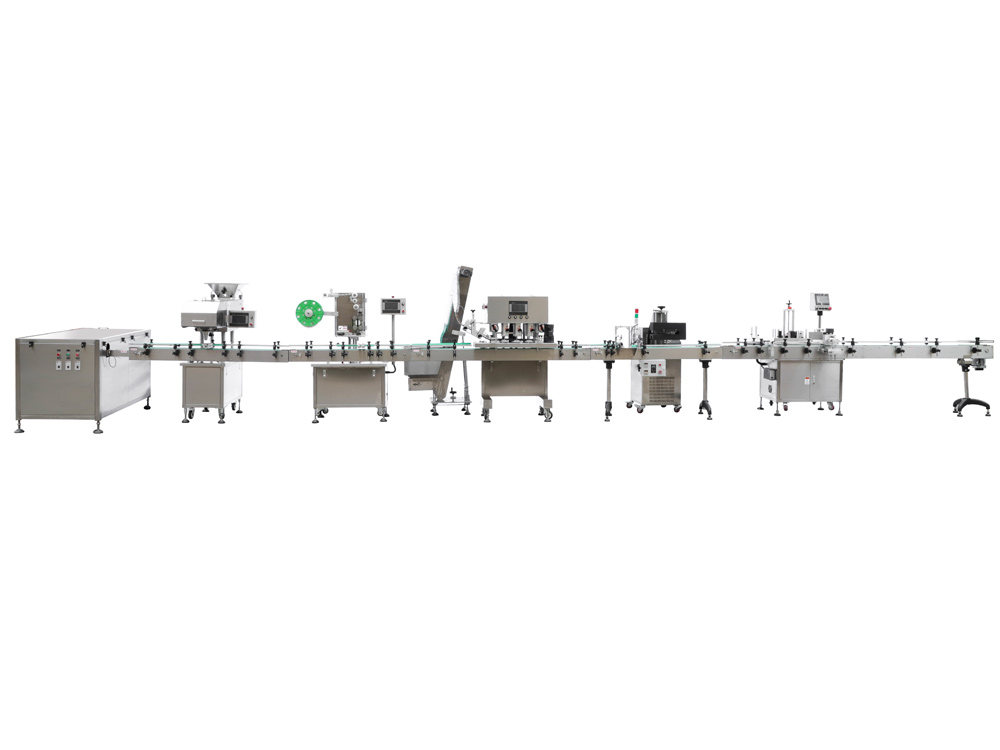

This fully automatic bottle counting and filling production line consists of a high-speed bottle sorting machine, an electronic counting machine, a desiccant feeding machine, a high-speed capping machine, an aluminum foil sealing machine, and a labeling machine. Suitable for the entire packaging process of tablets, pills, hard capsules, soft capsules, and other shaped tablets in industries such as pharmaceuticals, food, daily chemicals, and health products, including counting, capping, sealing, and labeling. This machine is widely used in industries such as pharmaceuticals, candies, and health products. According to customer needs, different single machines and multiple combinations can be used.

Features of the production line:

1. High efficiency: able to quickly and accurately complete counting and packaging tasks, improving production efficiency.

2. High degree of automation: reduce manual operations and lower labor costs.

3. Accurate counting: Ensure the accuracy of particle count and avoid errors.

4. High quality packaging: Ensure the integrity and sealing of the packaging.

5. Continuous production: achieving uninterrupted production processes and increasing production capacity.

6. Strong adaptability: able to adapt to particles of different shapes and sizes.

7. Adjustability: Parameters can be adjusted according to product filling requirements.

8. Good stability: reduces the occurrence rate of faults and improves equipment reliability.

9. Save raw materials: Accurate packaging control can reduce waste of raw materials.

10. Improve product hygiene: reduce human exposure and reduce pollution risks.

11. Quick conversion: Easy to switch packaging between different products.

12. Integration: It can be integrated with other devices to form an automated production line.

Product features

Multi channel electronic counting machine:

☆ Multiple pieces have a wide range of applications, and the same device can be used to can multiple pieces of products of different specifications and sizes. The switching between different specifications is simple and easy to adjust;

☆ Accurate counting, using an independent optical detection system to ensure high-level counting accuracy and speed;

☆ Adopting multi-level vibration feeding, each level can be adjusted separately for faster material separation speed and more uniform and smooth posture;

☆ The surface is made of stainless steel and non-toxic, chemically stable food grade non-metallic materials, which are easy to clean and have no dead corners;

☆ Equipped with photoelectric detection for missing or blocked bottles, it can effectively control the normal operation of the entire system. If there are no bottles or blocked bottles, it will automatically stop and run automatically after recovery;

Desiccant delivery machine:

☆ The cutting blade is controlled by a cylinder, with a durable and not easily worn blade edge. The cutting action is sharp, ensuring the integrity of the drying bag;

☆ PLC control, Chinese English dialogue control panel, can store ten sets of data, easy to adjust, and easy for operators to get started;

☆ The drying bag strip is driven by a stepper motor for conveying, ensuring stable and smooth feeding. With precise sensing by optical eyes, the positioning of the drying bag is accurate, which can effectively prevent the drying bag from cutting and contaminating the product;

Capping machine:

☆ The constant torque capping head ensures that the capping head stops rotating once the lid meets the tightness requirements, making it suitable for products with high tightness requirements;

☆ Photoelectric sensor detection, suspend operation due to bottle shortage or blockage, and automatically run after recovery;

☆ The lock cap head can be replaced to meet different bottle cap locking and capping requirements;

Labeling machine:

☆ Labeling has a wide range of applications, simple switching of labels between bottles, and convenient adjustment;

☆ High labeling accuracy, with a deviation correction mechanism for tape winding, good stability, smooth labeling, no wrinkles, and no bubbles;

☆ Excellent labeling quality, using elastic label covering belts, labeling is smooth and wrinkle free, improving packaging quality.