DESCRIPTION

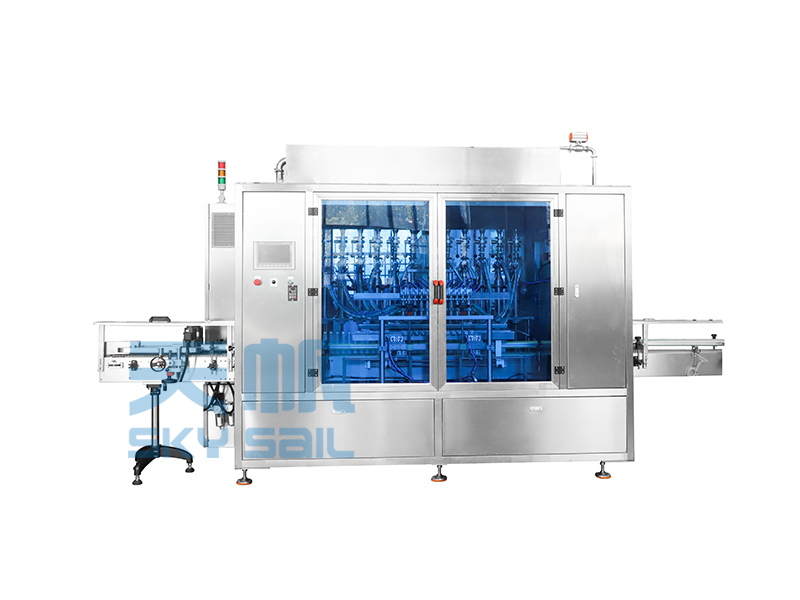

The TFTC-HS-12 head fully servo piston pump filling machine is an efficient and precise filling equipment widely used in industries such as food, beverage, and cosmetics. This article will introduce the working principle, characteristics, and applications of a 12 head fully servo piston pump filling machine.

The 12 head fully servo piston pump filling machine uses a servo motor to control the piston operation, accurately controlling the filling volume, and can be adjusted within the range of 0.5 milliliters to 500 milliliters. The device is easy to operate and can achieve automated production by controlling parameter settings through a touch screen. At the same time, the device also has an automatic cleaning function, reducing cleaning time and labor costs.

The filling accuracy of this equipment is high, with a filling error of less than ± 0.5%, which can meet various filling requirements. At the same time, the equipment is made of 304 stainless steel, which meets food grade hygiene standards and is easy to clean and maintain.

The 12 head fully servo piston pump filling machine is suitable for filling various liquid and semi liquid substances, such as sauce, oil, water, sauce, etc. Its multi head design allows for multiple production processes simultaneously, greatly improving production efficiency. This device can also be customized according to customer needs to meet different filling requirements.

In daily applications, the 12 head fully servo piston pump filling machine plays an important role. For example, in the food industry, this equipment is widely used for filling products such as jam, soy sauce, seasonings, etc. It can precisely control the filling volume of different products, ensuring product quality and production efficiency. In the beverage industry, this equipment can be used for filling products such as beverages and juices. Its high precision and efficiency make the production process more stable and reliable.

In summary, the 12 head fully servo piston pump filling machine is an efficient and precise filling equipment. Its working principle is simple and easy to operate. This equipment has the characteristics of high filling accuracy, automatic cleaning, and multi head design, and is suitable for filling various liquid and semi liquid substances. Widely used in industries such as food, beverage, and cosmetics, it provides a reliable solution for product filling.