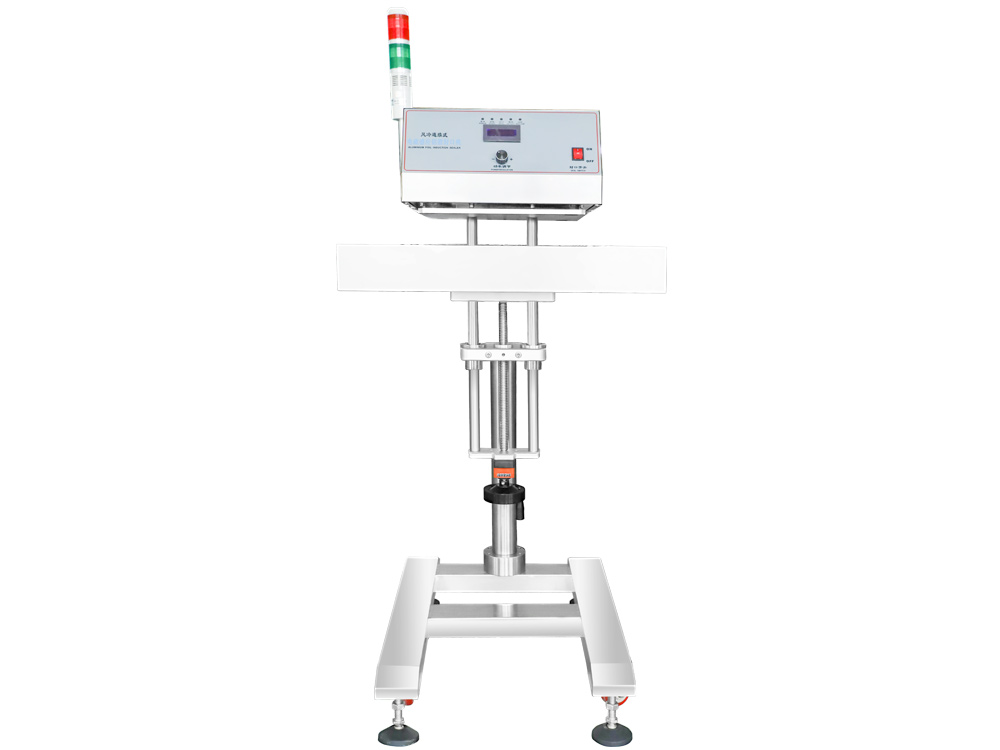

Equipment Introduction

This equipment is a new generation sealing equipment that replaces outdated processes such as cork plugs and wax immersion. It is an ideal sealing equipment that utilizes the principle of electromagnetic induction to instantly generate high heat on the aluminum foil on the bottle mouth, thereby fusing the aluminum foil onto the bottle mouth and achieving sealing purposes. After sealing with an aluminum foil sealing machine, the product has good moisture-proof and mildew proof effects, achieving the purpose of extending the product's storage period and anti-counterfeiting. Printing a trademark on aluminum foil can effectively prevent the production of counterfeit products. Specially used in the sealing process of industries such as medicine, pesticides, food, cosmetics, lubricants, etc. The materials of containers can be polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyester (PET), polystyrene (PS), and glass, and cannot be used for metal bottle bodies and caps.

Features of aluminum foil sealing machine products

◆ Sealing has a wide range of applications, simple switching between different specifications, and convenient adjustment;

◆ New intelligent module design, moisture-proof, anti-corrosion, dust-proof, and anti magnetic interference. Long service life, extremely low failure rate, and simple maintenance;

◆ The main generator adopts relatively new imported transistors, with CPU module control and protection functions. All functional components on the panel are clearly labeled and easy to operate;

◆ 4 copper wire induction coils, 3 fans, fast sealing speed, and good sealing effect;

◆ The height of the sensing head is adjustable, which can adapt to the sealing and packaging of containers of various heights;

◆ Fully air-cooled cooling system, efficient and high-speed, capable of working continuously for 24 hours;

◆ Stainless steel material, in compliance with GMP requirements;

◆ The sensing head and host of the same model can be interchangeable and interchangeable, effectively reducing usage costs;

◆ Flexible application, with automatic bottle splitting function, can be produced independently, or used in conjunction or embedded with assembly lines, suitable for large-scale production of products on assembly lines;

◆ Complete equipment supporting materials (including equipment structure, principle, operation, maintenance, repair, upgrade, etc.), providing sufficient guarantee for the normal operation of the equipment;

◆ Optional aluminum foil removal mechanism to prevent unsealed products from flowing out of the production line, ensuring safe use.